-

Small injection molded plastic bracket

·injection molding

·custom parts

·plastic holder

-

Custom injection molded rubber stopper

·injection molding

·custom parts

·plastic plug -

Flame retardant injection molded plastic cover

·injection molding

·custom parts

·plastic cover -

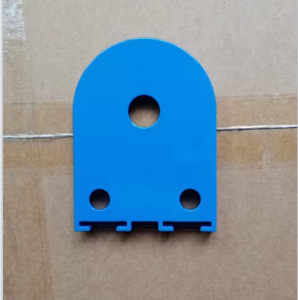

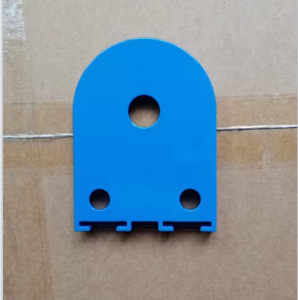

Injection Plastic Custom Brackets

·injection molding

·custom parts

·plastic holder -

Injection Plastic Custom Brackets

·injection molding

·custom parts

·plastic holder -

Injection Plastic Custom PA6 Nut

·injection molding

·custom parts

·plastic nut -

Customized UL94 V0 Flame Retardant Electronic Products Plastic Housing

·injection molding

·plastic plate

·UL94 V0 Flame retardant grade -

Custom Injection Molded Electronics Plastic Sheets

·injection molding

·custom plastic part

·plastic plate -

Custom injection molded plastic electronics body

·injection molding

·custom plastic part

·plastic main body of electronic product -

Custom Injection Plastic Electronics Housing

·injection molding

·custom plastic part

·plastic shell -

Custom Injection Plastic Battery Cover

·injection molding

·custom plastic part

·plastic battery cover -

Customized Injection Molded Plastic Laminations

·injection molding

·custom plastic part

·plastic cover

-

Dbh-15p (female) welding wire type needle white glue connector

Product Name: dbh-15p (female) welding wire type needle white glue

Temperature resistance: 230 degrees

Interface type: HDMI

Characteristics: high temperature resistance 230 ° C

Scope of application: widely used in all kinds of household appliances, electric toys

Digital products, modern office equipment, industrial control and monitoring communication equipment, etc. -

Louderspeaker gasket

Product Description: Louderspeaker gasket

Market or Client: Canada

Application: gasket for audio system /Louderspeakers

Material: NBR.

Processing: rubber molding.

Specialty of this item: Antistatic.

NOT FOR SALE. Mold ownership belong to our clients.

-

PF top and bottom cover for PG020 barbecue machine, PF injection, fireproof, heat resistant.

Description:

PF top and bottom cover for PG020 barbecue machine, PF injection, fireproof, heat resistant.

Material: PF (phenolic compound);

Weight: 730g;

Market: export to Denmark;

Customized design, latest version. Fireproof, heat resistant.

Bakelite, also known as bakelite and chemical phenolic resin, has high mechanical strength, good insulation, heat resistance and corrosion resistance. Therefore, it is widely used in various electrical manufacturing materials, such as switch, motor shell, kitchen handle, etc.

Bakelite injection molding products are characterized by insulation, high temperature resistance, no water absorption and high strength, so they are mostly used in electrical appliances. Because it has good insulation and high plasticity like wood, it is called bakelite. Bakelite is made of powdered phenolic resin, mixed with sawdust, asbestos or clay, and then thermosetting with a mold at high temperature. Phenolic resin is a kind of human synthetic resin. -

phenolic injection molding bakelite pot beads

This is a bakelite product used for electrical appliances. It can be used for all kinds of household appliances, switches and electrical products. Its main characteristics are insulation, high temperature resistance and high mechanical strength. The product size can be designed according to your drawings and is suitable for functional products used in various high-temperature environments. -

phenolic injection shell of electric rice cooker

SV plastic hardware CO.,LTD. is located in Huangyan Town, Zhejiang, China. It has been engaged in injection molding for more than ten years. It has bakelite, BMC injection molding and precision plastic injection molding. Its products are widely used in all kinds of kitchenware, electromechanical, home appliance accessories and precision plastic injection molding products, notebook, mobile phone auto parts shell, etc.

The company has a strong engineering team and is committed to creating high-quality products for customers. The company fully implements ISO9001 and iatf16949 quality management systems and has stable well-known customers at home and abroad. -

Car OEM front bumper

Market or Client: Germany;

Material: Mold -P20, molded parts -engineering PP /Compounded PP;

Processing: Injection.

Application: Car, OEM, injection;

Specialty of this item: OEM car parts, Big sized

Why are most of the interior and exterior trim parts in the automotive industry made of plastic materials? There is no other reason. Plastics have excellent material performance and various processing methods. Different processes such as injection molding, blow molding and blister can meet the molding requirements of different products, especially the complexity of automobile parts. The selection of injection molding machines of different models can meet the requirements of different materials such as automobile bumpers, instrument panels and automobile baffles Injection molding production of automotive parts with different dimensions and other characteristics.

Processing advantages of automobile complex plastic parts:

1. Plastics can be processed and formed at one time, with short processing time and guaranteed accuracy.

2. The elastic deformation characteristics of plastic products can absorb a large amount of collision energy, have a great cushioning effect on strong impact, and protect vehicles and passengers. Plasticized dashboard and steering wheel are used in modern cars to enhance cushioning. The front and rear bumpers and body trim strips are made of plastic materials to reduce the impact of objects outside the vehicle on the body. The plastic also has the function of absorbing and attenuating vibration and noise, which can improve the ride comfort.

3. Plastic has strong corrosion resistance and will not corrode if damaged locally.

4. By adding different fillers, plasticizers and hardeners, plastics with required properties are prepared to meet the application requirements of different parts on the vehicle. What's more convenient is that different colors can be called out through additives to save the trouble of painting. Some plastic parts can also be electroplated. -

Bakelite lamp cap

Electric wood board, also known as glue board, is made of high-quality bleached wood stacking paper and cotton lint paper as reinforcement, bakelite and phenolic resin made by the reaction of high-purity and fully synthetic petrochemical raw materials as resin adhesive.

Bakelite is made of powdered phenolic resin, mixed with sawdust, asbestos or clay, and pressed out of the finished product by mold at high temperature. Phenolic resin is a kind of synthetic resin in the world.

1. T385j injection molding, while t373j has good electrical performance, heat resistance and flame resistance.

2. Bakelite powder can withstand a temperature of 275 ℃.

3. The average shrinkage of bakelite powder is 0.8%, and the expansion coefficient of bakelite bakelite after molding and curing is 0.14%.

4. Bakelite powder will not burn, only coking.

5. Composition: phenolic resin, wood powder, hardener and additives, including curing agent, plasticizer, colorant, lubricant and curing accelerator.

6. Phenolic resin: the resin obtained by polycondensation of phenolic compounds and aldehydes (mainly the condensate with) is called phenolic resin.

7. Bakelite: phenolic resin has high mechanical strength and stable performance, hardness, wear resistance, heat resistance, flame resistance, resistance to most chemical reagents, low moisture absorption and excellent electrical insulation performance. It is an ideal insulating material, commonly known as bakelite.

8. Bakelite is plasticized at 70 ~ 90 ℃, has viscosity and fluidity at 90 ~ 120 ℃, and suddenly hardens at about 160 ℃, forming non melting solid and hardening reaction. -

Plastic shell of electric iron

The molding methods of bakelite products include pressing molding and injection molding, so most bakelite materials are also divided into pressing materials and injection materials. Generally, the cost of press molding is low, but the labor intensity of workers is high, the precision of products is low, and the yield is not high. Injection molding is better than press molding. Although its one-time investment cost is high, the labor intensity of workers is small, the precision of products is high, and the yield is also high. Therefore, it has the trend of gradually replacing press molding.

There is usually a heat shield at the top and bottom of the die. This is mainly because the temperature needs to be increased to 160-180 ℃ when the bakelite mold is formed. The device is added to avoid the mold temperature from transmitting to other parts of the machine, affecting the machine performance and reducing heat loss. At present, our products adopt this structure.