-

Junction box housing

BMC process is characterized by:

(1) Easy to operate. The whole production process is easy to realize mechanization and automation, has high production efficiency, and improves the working environment and working conditions of wet forming.

(2) The product is highly unpredictable. The different requirements of different products can be met by changing the type and formula of components and changing the molding process. Such as corrosion resistance, insulation, heat insulation, zero shrinkage, flexibility, low density, high strength, class a surface, antistatic, etc.

(3) Good molding fluidity. It can form products with complex structure, especially suitable for making large thin shell special-shaped products. It can realize the functions of variable thickness of products with inserts, holes, bosses, stiffeners, threads and so on.

(4) The product is bright and clean inside and outside and accurate in size. It is suitable for making automotive peripheral parts, electrical parts, mechanical parts, anti-corrosion containers and other products. Suitable for large-scale production and low cost.

(5) The reinforcing material has no damage in the process of production and molding, uniform length and high product strength. It can carry out light structural design and bright color. -

Plastic shell

Product Description: Plastic shell

Market or Client: France

Application: Not Known

Material: ABS.

Processing: Injection.

Specialty of this item: good mating quality.

NOT FOR SALE. Mold ownership belong to our clients.

-

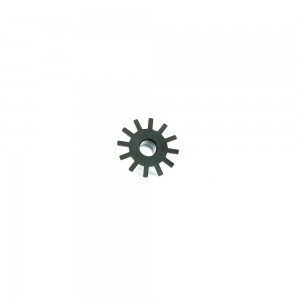

Louderspeaker gasket

Product Description: Louderspeaker gasket

Market or Client: Canada

Application: gasket for audio system /Louderspeakers

Material: NBR.

Processing: rubber molding.

Specialty of this item: Antistatic.

NOT FOR SALE. Mold ownership belong to our clients.

-

Injection Mold for POM Material Pulley Spring Bushing

Product Description: Delrin POM material, Mold steel MOVCR12, Pulley Spring bushing /Mold for POM plastic injection part

Mold Steel (Core & Cavity/ Mold Base): MOVCR 12 / P20

Part's Material: Delrin

Application: industrial

Market or Client: USA -

AP-R1 & AP-R1 WS Plate /injection Molds

Product Description: Molds for Germany, ABS/PC molds, cheaper as used moulds /custom plastic injection Mold

Mold Steel (Core & Cavity/ Mold Base): MOVCR 12 / P20

Part's Material: ABS,PC

Application: industrial

Market or Client: Germany

Specialty of these molds: each mold of 2 caviities mold, one cavity of gloss finish, the other cavity of VDI34 texture finish,

"Rotatable nozzle for a quick change between high gloss and structure texture"

---hot runner, with valves control to close or open the cavity you want to inject, which means you can inject the gloss part (by shutoff the VDI34 cavity valve) or inject the VDI34 part (by shutoff the gloss cavity valve) or inject both cavities at the same time (by opening both valves).

Automatic falling /automatic running. -

Custom plastic spoon injection Mold

Product Description: Custom high polished high gloss plastic spoon American standard injection Mold and plastic injection part manufacturing.

Mold Steel (Core & Cavity/ Mold Base): Core & Cavity 718 steel, Mold Base P20 steel

Part's Material: PP

Application: industrial

Market or Client: USA -

-

Car OEM front bumper

Market or Client: Germany;

Material: Mold -P20, molded parts -engineering PP /Compounded PP;

Processing: Injection.

Application: Car, OEM, injection;

Specialty of this item: OEM car parts, Big sized

Why are most of the interior and exterior trim parts in the automotive industry made of plastic materials? There is no other reason. Plastics have excellent material performance and various processing methods. Different processes such as injection molding, blow molding and blister can meet the molding requirements of different products, especially the complexity of automobile parts. The selection of injection molding machines of different models can meet the requirements of different materials such as automobile bumpers, instrument panels and automobile baffles Injection molding production of automotive parts with different dimensions and other characteristics.

Processing advantages of automobile complex plastic parts:

1. Plastics can be processed and formed at one time, with short processing time and guaranteed accuracy.

2. The elastic deformation characteristics of plastic products can absorb a large amount of collision energy, have a great cushioning effect on strong impact, and protect vehicles and passengers. Plasticized dashboard and steering wheel are used in modern cars to enhance cushioning. The front and rear bumpers and body trim strips are made of plastic materials to reduce the impact of objects outside the vehicle on the body. The plastic also has the function of absorbing and attenuating vibration and noise, which can improve the ride comfort.

3. Plastic has strong corrosion resistance and will not corrode if damaged locally.

4. By adding different fillers, plasticizers and hardeners, plastics with required properties are prepared to meet the application requirements of different parts on the vehicle. What's more convenient is that different colors can be called out through additives to save the trouble of painting. Some plastic parts can also be electroplated. -

Bakelite electric appliance base

Select high-quality bakelite materials with guaranteed quality, high temperature resistance and insulation.Using imported bakelite powder, Seiko, to meet all your needs. Product features: 1. The product is smooth without burr, high quality workmanship, fastening and durability. 2. Excellent quality, good quality and excellent price. Imported processing equipment is selected. 3. Keep the drawings confidential, strictly enforce the drawing management system and eliminate the risk of disclosure.... -

Bakelite electrical enclosure

Select high-quality bakelite materials with guaranteed quality, high temperature resistance and insulation.Using imported bakelite powder, Seiko, to meet all your needs. Product features: 1. The product is smooth without burr, high quality workmanship, fastening and durability. 2. Excellent quality, good quality and excellent price. Imported processing equipment is selected. 3. Keep the drawings confidential, strictly enforce the drawing management system and eliminate the risk of disclosure.... -

Bakelite motor accessories

Select high-quality bakelite materials with guaranteed quality, high temperature resistance and insulation.Using imported bakelite powder, Seiko, to meet all your needs. Product features: 1. The product is smooth without burr, high quality workmanship, fastening and durability. 2. Excellent quality, good quality and excellent price. Imported processing equipment is selected. 3. Keep the drawings confidential, strictly enforce the drawing management system and eliminate the risk of disclosure.... -

Bakelite handle

Select high-quality bakelite materials with guaranteed quality, high temperature resistance and insulation.Using imported bakelite powder, Seiko, to meet all your needs. Product features: 1. The product is smooth without burr, high quality workmanship, fastening and durability. 2. Excellent quality, good quality and excellent price. Imported processing equipment is selected. 3. Keep the drawings confidential, strictly enforce the drawing management system and eliminate the risk of disclosure.... -

BMC security products

This is a BMC material security product, which can be used for all kinds of motors, meters, electrical and other products. Its main characteristics are insulation, high temperature resistance and high mechanical strength. The product size is 103 in diameter, 100 in height and 30 to 50 in hardness. It is suitable for functional products used in various high-temperature environments. -

Plastic Bakelite shell

Specification Product name Plastic Bakelite shell category (Molding/Plastic Parts/Metal Parts/Assembling/Racing parts/Others) Plastic Parts Material Bakelite Description Select high-quality bakelite materials with guaranteed quality, high temperature resistance and insulation.Using imported bakelite powder, Seiko, to meet all your needs.We have been engaged in injection molding for more than ten years, including bakelite, BMC injection molding and precision plastic inject... -

Bakelite electrical enclosure

Product features: 1. The product is smooth without burr, high quality workmanship, fastening and durability. 2. 2. Excellent quality, good quality and excellent price. Imported processing equipment is selected. 3. Keep the drawings confidential, strictly enforce the drawing management system and eliminate the risk of disclosure. -

BMC ceiling

BMC integrated ceiling is made of aerospace polymer nanocomposites by heat curing molding process. It is a new type of polymer composite molding decorative material with a variety of excellent properties. It can be used in all occasions requiring ceiling treatment, especially in public places such as office buildings, hospitals and schools. It has excellent fire and flame retardant performance. For the home decoration market, BMC ceiling is water-resistant, dirt resistant, corrosion-resistant... -

Electric welding tongs

Production of electric welding tongs with DMC material (BMC material) features: (1) High temperature resistance of insulation parts of DMC material (BMC material) electrode holder: since the thermal deformation temperature of glass fiber material of DMC material (BMC material) is 240 ℃, the insulation parts of BMC electrode holder can maintain good rigidity at high temperature and can be used for a long time at 150 ℃. Moreover, it has excellent low temperature resistance and can also be used ... -

-

-

Die Casting Mold

Zinc Alloy without Surface Treatment: Zinc Alloy with Surface Treatment: 1 Without & with Anodize Surface Treatment: 2 With & without Plating (chrom plating) -Front Side: With & without Plating (chrom plating) -Back Side: 3 Without & with Powder Coating – Front Side: Without & with Powder Coating - Back Side: 4 With & without Vibration Milling – Front Side: With & withou...