PC/ABS, as the main material of automobile interior trim and electronic and electrical shell, has its irreplaceable advantages. However, in the injection molding process, improper materials, mold design and injection molding process are likely to lead to peeling on the product surface.

In general, when the shear rate of the melt is greater than 50000, PC/ABS materials will be prone to peeling. In addition, what other factors will affect the peeling of injection molded parts?

Material factor

The fluid fracture under high shear leads to the peeling phenomenon of the product. Compared with other materials, the two-phase structure of PC/ABS is more prone to fluid fracture and two-phase separation under high shear, and then peeling phenomenon occurs. For PC/ABS materials, the two components of PC and ABS are partially compatible, so appropriate compatibilizers must be added in the modification process to improve their compatibility. Of course, we need to eliminate the defective peeling caused by mixing.

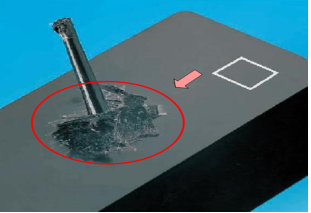

Mold factor

The principle of mold design shall follow the direction of minimizing shearing. In general, the products with dense dermatoglyphic surface are more likely to produce peeling phenomenon (caused by the friction and shear of the melt in the cavity and the inner wall of the cavity during high-speed filling); At the same time, in the gate design, if the gate size is too small, it will cause excessive shear when the melt passes through the gate, which will lead to the peeling of the product surface.

Process factor

The main direction is to avoid excessive shearing. When it is difficult to fill the product, it can be improved by high speed and high pressure. However, high speed and high pressure will lead to excessive shear force at the gate, and the shear between the melt and the inner wall of the cavity and the shear between the melt core and the skin will also increase sharply; Therefore, in the actual injection process, we can also consider ways to increase the injection temperature/mold temperature and improve the material fluidity to reduce the flow resistance in the actual filling process, so as to avoid excessive shear caused by high speed and high pressure.

Post time: Dec-02-2022