In mold manufacturing, mold exhaust is a very important link. Mold exhaust can represent the overall structure of the mold to the greatest extent. Even if an excellent mold does not have good exhaust, it is impossible to produce products with stable quality. A good mold should have good airtightness and can ensure the free exhaust of gas, rather than highly compressed gas. What is the standard for mold exhaust?

First of all, we should understand that unreasonable exhaust will cause the following defects:

1. Gas accumulation will erode the mold surface and parting line;

2. Color problem: color difference occurs, making the color black or bright; The dimpled surface is bright and foggy

3. To increase mold polishing: waste time, cost and make steel easy to corrode;

4. It is impossible to make the product meet the standards required by customers;

5. Too many binding lines will be produced (the binding is not firm and beautiful);

6. It will waste too much injection pressure and increase the difficulty of the injection molding machine;

7. It is necessary to use too high barrel temperature (increase the working difficulty of injection molding machine, temperature control error, material performance deviation, increase cycle time);

8. It will reduce the level of materials;

9. It will lead to product deformation;

10. The struggling force of high-pressure gas in the mold cavity will increase the cycle instability, and it will often need to adjust the machine to solve quality problems;

11. It makes the work of technicians, QA, operators and mold room personnel more difficult.

Second, let’s understand the reasonable exhaust technical requirements:

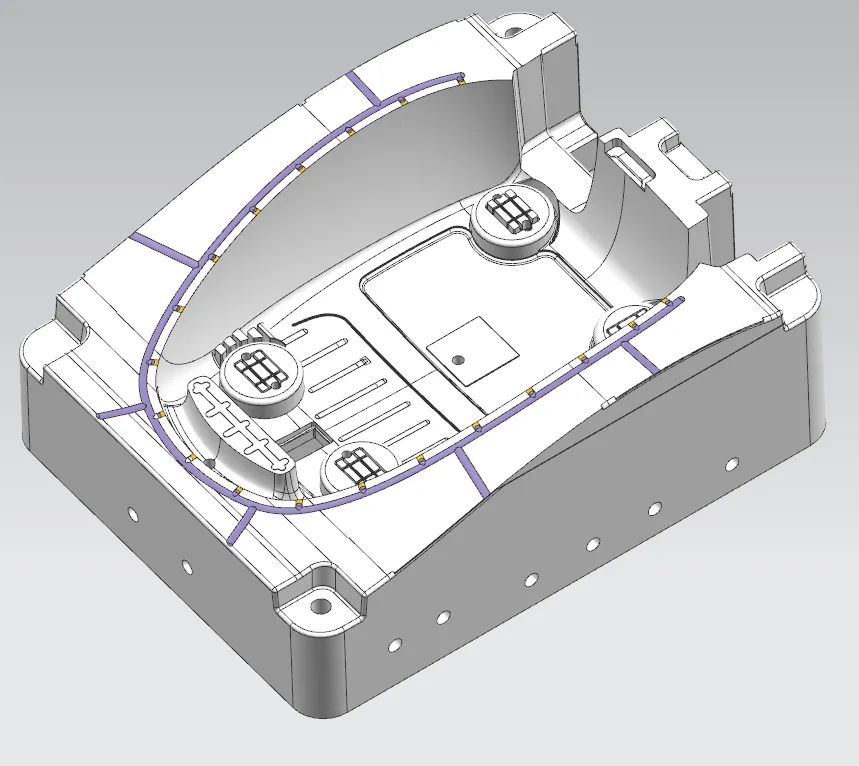

The all-around exhaust structure should be made as far as possible, and the depth should be within the plastic overflow value. The all-around exhaust is the best, but 1/2 of the steel should be left on the mold closing line to compensate the pressure.

If it is impossible to exhaust the whole circumference due to the irregularity of the PL surface, the better method is to use a 12mm wide exhaust groove to the mother mold, and the gas must be finally discharged into the atmosphere. The exhaust groove should be processed with a flat-bottomed chamfered milling cutter as far as possible. If it is necessary to use a spherical milling cutter, it should be calculated that the processing depth is consistent with the depth of the flat-bottomed processing before it can be used. The length of the exhaust sealant is the most easily ignored by most people, and is related to the proper exhaust problem;

There are many different sizes on this issue. The material supplier’s specifications range from 3 to 5 mm, but experience has proved that if the length is greater than 3 mm, it will no longer play a good role. Therefore, for safety reasons, we specify a standard of 3 mm, and the exhaust depth depends on the molding material. If in doubt, please refer to the processing specifications.

One of the most common misconceptions is that too much exhaust leads to a front, but in fact, the opposite direction is right. Unreasonable exhaust requires excessive pressure. When the gas is allowed to exhaust, the rubber will come out with the gas, and the only reason for the front is that the depth of the gas groove is too deep.

Another common problem is that when the parts cannot be fully vented, the last filling position and the second last filling position must be considered, and these two positions must be vented. For deep bone position, column position, small needle dispensing position or thin glue position, special consideration shall be given to exhaust, or flat ejector pin, semi-needle structure or exhaust steel, or even vacuum exhaust device shall be used.

Post time: Jan-31-2023